Stereolithography is one of the methods used in 3D printing to create 3D objects. The 3D printer which uses this method is called a stereolithograph. Liquid plastic (liquid ultraviolet curable photopolymer resin) is used to build a 3D object by systematically hardening the liquid plastic using a UV laser to form a solid shape. This method was created to facilitate rapid prototyping in industry but today it has a much wider application. It was created by Charles Hull, the co-founder of 3D Systems in 1986. SL is used mostly in businesses and industry rather than in home 3D printers which tend to use other additive manufacturing methods.

How Does Stereolithography Work?

Like all methods of 3D printing the creation process starts with a design made using a CAD (Computer Aided Design). The design can be modified and optimized on the computer before being printed. Once the CAD file has been created it is turned in to a STL file (Standard Tessellation Language). The 3D printer is capable of “reading” the STL file as it includes only the surface geometry of the shape and no other details like texture or color. The STL file creates virtual slices of the CAD model so that the printer can interpret how it should build the object.

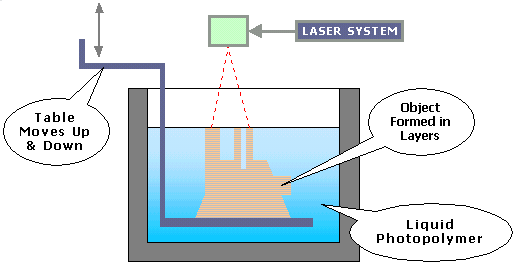

The stereolithograph has a vat filled with liquid plastic (photopolymer). A perforated platform is lowered into the vat and submerged between 0.05mm and 0.15mm below the surface of the liquid plastic. The 3D printer has a UV laser which then aims at the platform and traces out the pattern of the first layer of the object. As the laser touches the thin layer of liquid plastic on the platform the plastic hardens instantly. Then the 3D printer automatically lowers the perforated platform fractionally exposing a new layer of liquid plastic and the laser repeats the movement “painting” the next and successive layers of the object. Each layer hardens in turn as the laser and plastic interact and bonds with the preceding layers. The forming object requires supporting material. By the time the object is completed it is fully submerged in the vat.

On completion the platform is raised and the 3D object can be removed. It is then cleaned in a liquid solvent to remove any excess resin. The object then needs to be baked in a UV oven to cure the plastic further.

Advantages and Disadvantages of Stereolithographic 3D Printers

A Stereolithographic printer produces objects with smooth surfaces which mean there is little manual work necessary after the 3D printing process. However it all depends on the quality of your SL printer. SL printing can take a long time for example a small object could take as long as 6-12 hours. The speed at which your object is formed depends on the quality and size of the SL printer. SL prototypes are of an extremely high quality as they can reproduce intricate details accurately. The resulting 3D objects are also durable and relatively inexpensive.

3D-Print Today is an online news magazine bringing you up to date on all the latest news from the 3D Printing Industry. We work hard on finding interesting and unique news stories and fresh trends on the market.

Our online magazine provides a compelling blend of daily articles, fresh news, blog posts and opinions, as well as videos and visuals across all platforms through our main website, our mobile application and the social media network; all contains the detailed information and up to date news, for you to discover the amazing world of 3D Printing.

245 Greene Street

New York, NY 10012